Ever spend a ton on a clutch job, only to find the car still shudders or makes weird noises right after? One of the top reasons is a messed-up flywheel, hiding right behind your clutch. So, do you really need to swap your flywheel when you’re doing the clutch? The short answer: sometimes, but not always. It comes down to how beat up your old one is, and which kind of flywheel you're working with in the first place.

Ignoring a worn flywheel isn’t just asking for clutch problems. It can lead to rough gear changes, vibrations, and sometimes, put all that money you just dropped on a repair straight down the drain. Some cars get away with just resurfacing the flywheel, while others—especially those with dual-mass types—have fewer second chances. If you’re already pulling apart the transmission, checking your flywheel’s condition is a no-brainer. Getting it right now saves a lot of hassle later.

- The Flywheel: What It Does (and Why It Matters)

- When Do You Actually Need a New Flywheel?

- How to Check If Your Flywheel Is Worn Out

- Single-Mass vs. Dual-Mass: What Difference Does It Make?

- Tips for a Smoother, Longer-Lasting Clutch Job

The Flywheel: What It Does (and Why It Matters)

The flywheel is one of those parts you rarely see, but your manual car wouldn’t work without it. It’s a big, round piece of metal bolted to the back of your engine. When you press the clutch, the flywheel is right there, connecting and disconnecting your engine from the transmission. Its main jobs? Smoothing out the engine’s rotation, storing a bunch of energy to keep things running between combustion cycles, and giving the starter motor something to grab when you fire up the car. Basically, it helps your ride run smoother and makes the clutch system work.

If your flywheel is trashed, it’s going to cause clutch slippage, chatter, or vibrations you’ll definitely notice. And here’s an overlooked fact: a flywheel’s condition can make or break your clutch’s lifespan. Put a new clutch on a grooved or warped flywheel, and chances are you’ll be doing this job again sooner than you planned. That means wasted cash and time—and no one wants that.

Check this out—flywheel mass and health even affect how easy it is to shift gears, especially at high RPMs. If you’re into quick launches or often find yourself in heavy traffic, a solid flywheel can make your car less annoying and more enjoyable to drive. For those who love stats, here’s a quick comparison of flywheel types and their common performance traits:

| Type | Average Weight (lbs) | Durability | Typical Use |

|---|---|---|---|

| Single-mass | 15-30 | High | Performance, racing, economy cars up to mid-2000s |

| Dual-mass | 20-40 | Lower (parts wear faster) | Modern daily drivers, comfort-focused vehicles |

When you’re thinking about a flywheel replacement, realize it’s not just about bolting in a new clutch. You’re setting the foundation for how your car feels every time you drive. Spending a little time here pays off down the road.

When Do You Actually Need a New Flywheel?

Let’s get real—nobody wants to spend more than they have to, but skipping a worn flywheel when replacing your clutch can backfire. The best move? Take a hard look at the flywheel whenever the clutch is out. If you see blue spots from heat, deep grooves, cracks, or the surface looks uneven, that’s a red flag. Any of these can cause your new clutch to slip, chatter, or wear out way faster than expected.

If you’ve got a flywheel that’s cracked, warped, or dished (where the center sits lower than the edges), it definitely needs to go. Cracks can be dangerous—sometimes tiny, sometimes big, they only get worse and can even cause the whole thing to break apart. That’s why most mechanics say never reuse a cracked or seriously damaged flywheel, even if you’re tempted to save cash.

For those with dual-mass flywheels (common in a lot of newer manual transmissions and diesel cars), don’t expect to just resurface and move on. When these wear out, the springs inside get sloppy or even break. If it rattles, you feel weird vibrations, or the surface is chewed up, replacement is usually your only option. Shops see a lot of dual-mass flywheels fail quietly, so don’t skip this check.

Bizarre smells from the bellhousing area—kind of a burnt toast vibe—usually mean the flywheel overheated. If you’ve been driving with a slipping clutch for a while, the heat can harden the metal and even cause hotspots. In this case, new clutch plus old flywheel is almost always asking for trouble.

- Change your flywheel if you see any cracks, major heat damage, or deep grooves.

- Replace dual-mass flywheels if they rattle or the springs inside are loose.

- If the surface is glazed, uneven, or too thin to resurface, it’s time for a new one.

A quick inspection can save you hundreds down the road, so grab a flashlight and take a solid look—don’t rely on guesswork or just what the shop says. Your clutch job will last a lot longer if you make the right call up front.

How to Check If Your Flywheel Is Worn Out

Once you pull the transmission to get to your clutch, checking the flywheel is a step you can't skip. If you get this wrong, your new clutch might not last long, and you’ll just end up back under the car way too soon. A damaged flywheel is one of the top reasons fresh clutch kits don’t deliver a smooth ride.

Here's what you need to look for:

- Surface cracks or hot spots: These show up as blue or black patches. It means your flywheel's taken some heat, usually from slipping. Deep cracks are a no-go—replace it.

- Grooves and scoring: If it looks like a scratched-up old vinyl record, don’t risk it. Uneven surfaces ruin clutch contact and wear out your new disc.

- Glazing: A super shiny, glass-like surface means the flywheel got too hot and isn’t letting the clutch grip right. Sometimes you can resurface this, but if it’s bad, it’s time for a new one.

- Loose ring gear: If the ring gear (the part with teeth the starter hits) feels wobbly or you notice teeth missing, swap the flywheel. You don’t want starter trouble down the road.

- Side-to-side play: Try to rock the flywheel back and forth. If it moves around, it’s done. Especially true for dual-mass flywheels where internal springs can fail.

Some drivers try to cheap out with a quick look, but plenty of issues hide until you’re up close. Lighting helps, and don’t be shy about running your finger over the surface—you’ll feel grooves better than you see them.

| Sign | What It Means | Replace or Resurface? |

|---|---|---|

| Blue heat spots | Overheating/slipping | Usually resurface; replace if deep |

| Cracks | Excess heat/fatigue | Always replace |

| Scoring/grooves | Worn from old clutch/contact | Resurface if not too deep |

| Loose ring gear | Starter/engagement issues | Replace |

| Side-to-side play | Internal failure (mostly dual-mass) | Replace |

If you’ve got a single-mass flywheel and it just looks a bit rough, most machine shops will resurface it for 50-100 bucks. But with dual-mass types, if there’s play or if it feels loose, don’t mess around—most of these can’t be resurfaced safely. Better to replace than risk another headache.

One last tip: always check manufacturer specs. Every car is a bit different, and some automakers don’t even allow resurfacing on newer models. Spending a few more minutes checking now saves you way more money (and swear words) later.

Single-Mass vs. Dual-Mass: What Difference Does It Make?

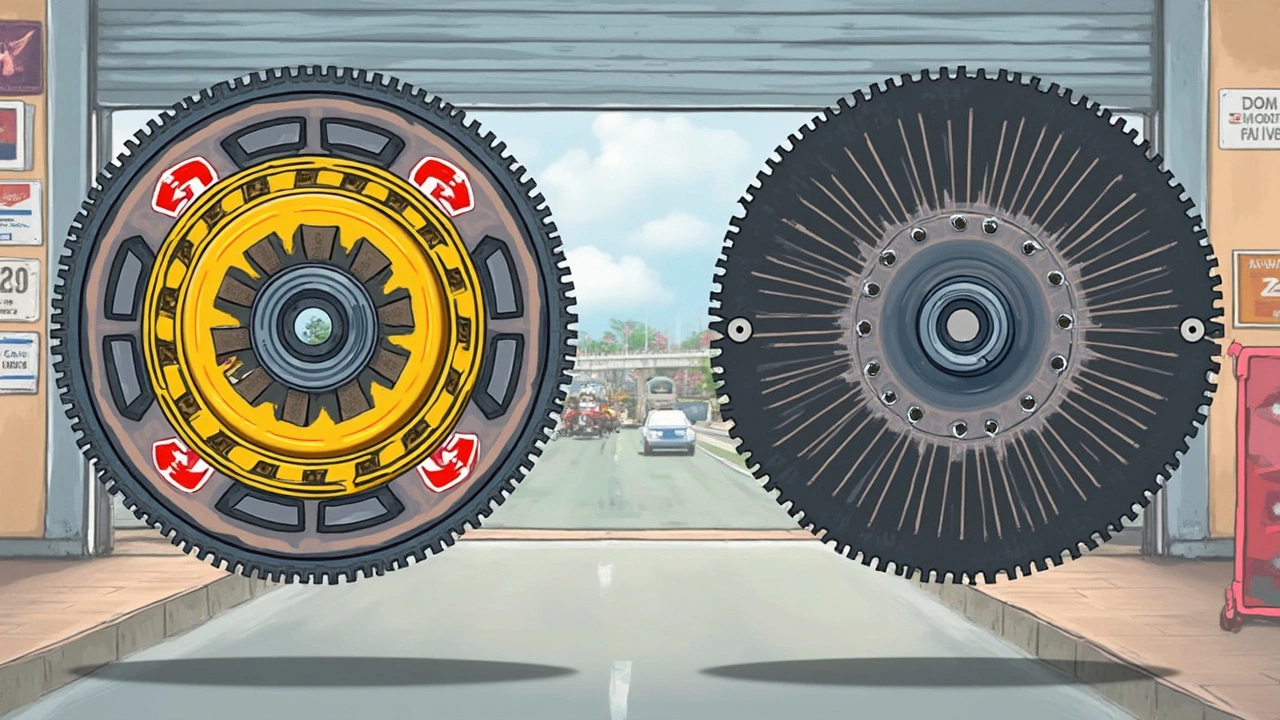

If you start talking clutch replacement, someone will ask, “Is it single-mass or dual-mass?” Here’s why it matters: these two types of flywheels don’t just look different, they actually work in totally different ways, and what you do with them during a clutch replacement can save or waste a pile of money.

Flywheel types break down like this:

- Single-mass flywheels (SMF): It’s basically a chunk of metal that spins. These are simple, solid, and pretty tough. You’ll find SMFs in most older cars, many sports cars, and trucks. If there are grooves, heat spots, or scoring, shops can usually machine or "resurface" them to like-new condition. Tossing one out is rare unless it’s cracked or worn down past spec.

- Dual-mass flywheels (DMF): These are more complicated. BMWs, newer Volkswagens, and a lot of modern diesels use them for a smoother and quieter ride, especially at low speeds. Inside, there are springs and moving bits to absorb vibrations. The catch? You can’t just resurface most DMFs—if they’re worn or make rattling sounds, they should be swapped. Their price tag hurts, but skipping it can trash a new clutch pretty fast.

It’s not just hype—here’s a quick comparison:

| Single-Mass Flywheel | Dual-Mass Flywheel | |

|---|---|---|

| Reusability | Can resurface if not cracked | Usually must replace if bad |

| Cost | $60 - $200 (average) | $400 - $1,200 (can be more) |

| Driving Feel | Sporty, direct connection, noisier | Smoother, quieter, more comfort |

Lots of folks try to “convert” a DMF setup to single-mass because it’s cheaper, but it isn’t always perfect—you get more gear rattle and some cars don’t like the switch. If you haul heavy loads or want better durability, single-mass can make sense. If you want factory-fresh smoothness, stick with dual-mass.

Quick tip: If you hear clunking when turning off the engine, or gear rattle at idle on a DMF car, don’t ignore it. Those are warning signs. And if you’re shopping for clutch kits, always check if it includes a flywheel—lots of DMF kits do, but SMF kits usually don't unless you’re doing a conversion.

Tips for a Smoother, Longer-Lasting Clutch Job

If you’re already spending money and time on a clutch replacement, it pays to do it right so you’re not crawling back under the car in a year. Here’s what makes a difference for keeping your clutch, and your flywheel, working like they should for as long as possible.

- Clean Everything: Clutch install is no place for dirty hands. Make sure surfaces are oil-free. Even a bit of grease where the clutch bites can cause slips or weird engagement problems.

- Replace Related Parts: Always swap the pilot bearing (or bushing) and the release/throwout bearing. Skipping these is asking for noise or trouble down the road.

- Don’t Cheap Out on the Kit: Bargain clutch kits often cut corners on friction material or springs. Spending a bit more up-front usually pays off at 50,000+ miles later.

- Check the Rear Main Seal: This seal sits right in front of the clutch, and a leak here ruins clutches fast. If you see oil, don’t ignore it—replace the seal while the transmission is out.

- Torque Everything Properly: Follow the specs, especially for pressure plate and flywheel bolts. Use a torque wrench. Over-tightened or loose bolts lead to warping, vibration, or even failure.

- Break In the New Clutch: Most new clutches need 300 to 500 miles of easy driving to seat properly. No hard launches or burnouts at first. This helps the material mate to the flywheel and pressure plate for longer wear.

People often forget that even the best new clutch can’t fix worn hydraulic parts or a warped flywheel. Here’s a quick table of what most shops recommend replacing along with the clutch:

| Part | Why Replace? |

|---|---|

| Clutch Kit (Disc, Plate) | Core friction components |

| Throwout/Release Bearing | Common failure, noisy when worn |

| Pilot Bearing/Bushing | Causes wobble or vibration if bad |

| Rear Main Seal | Prevents oil leaks onto clutch |

| Flywheel (or Resurface) | Smooth surface for clutch grip |

| Hydraulic Components | Weak hydraulics lead to poor engagement |

Sticking with quality parts and a little patience with break-in really does stretch how long your clutch kit lasts. Do it all at once, and it’ll feel like you’re driving a new car—without getting burned on repeat repairs.