Suspension Problem Diagnostic Tool

Describe Your Suspension Symptoms

Select all symptoms you're experiencing with your vehicle's suspension:

Suspension Diagnosis Results

Select symptoms above and click "Diagnose Suspension Issue" to get your results.

When your car starts feeling bouncy, drifts in corners, or makes clunking noises, the suspension is probably the culprit. Figuring out exactly what’s wrong can save you a costly repair shop visit and keep your ride safe. This guide walks you through the signs, the visual checks, the road test, and the tools you need to reliably diagnose a suspension problem.

Key Takeaways

- Identify the most common symptoms: uneven tire wear, knocking sounds, poor handling, and sagging ride height.

- Perform a quick visual inspection before you hit the road - look for leaks, broken bolts, and worn bushings.

- Use a simple bounce test and ride‑height gauge to pinpoint faulty shocks or struts.

- Know when a DIY fix is safe and when a professional mechanic should take over.

- Regular maintenance, like lubricating bushings and checking alignment, prevents many suspension issues.

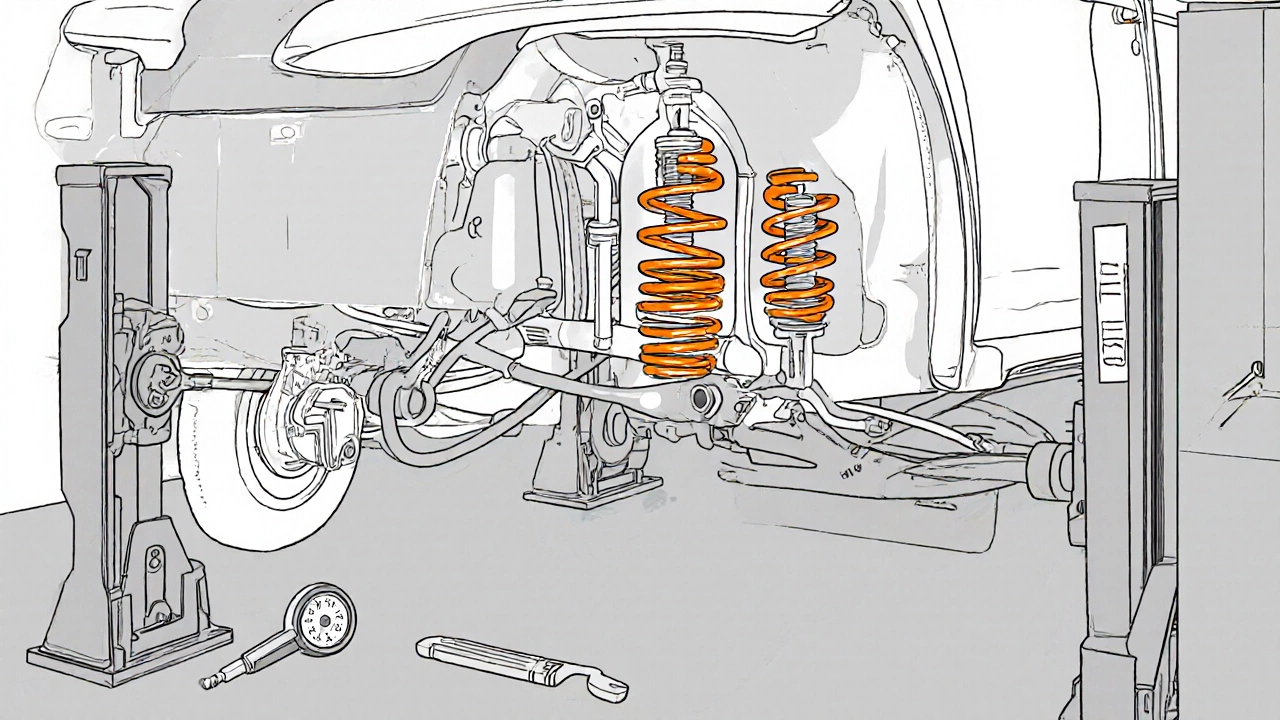

Understanding Vehicle Suspension

Vehicle suspension is a system of springs, dampers, linkages, and other components that supports the car’s weight, absorbs road shocks, and maintains tire contact with the road. It consists mainly of springs, shock absorbers or struts, control arms, and various bushings. Each part works together to keep the wheels aligned and the chassis stable. When one piece wears out, the whole feel of the car can change dramatically.

Common Symptoms of a Faulty Suspension

Before you lift the car, listen and feel. The most frequent clues include:

- Uneven or rapid tire wear - often a sign of mis‑alignment or worn bushings.

- Clunking or knocking noises when going over bumps.

- Excessive body roll during cornering.

- Vehicle sagging toward one side or a noticeable dip in ride height.

- Vibrations that intensify at higher speeds.

These symptoms map to particular components, as shown in the table below.

| Symptom | Probable Cause | Component to Inspect |

|---|---|---|

| Clunking over bumps | Loose or broken parts | Control arm bolts, bushings |

| Excessive bounce | Damped shock failure | Shock absorber or strut |

| Uneven tire wear | Mis‑alignment or worn bushings | Wheel alignment settings |

| Vehicle sagging on one side | Spring breakage or weak coil | Springs |

| Vibrations at speed | Wheel imbalance or worn tire | Tire condition and balance |

Visual Inspection Checklist

- Park on a level surface. Check that the car sits evenly. Any dip is a red flag.

- Look under each wheel for oil leaks - fluid on a shock absorber usually means a seal failure.

- Inspect springs for cracks, broken coils, or uneven spacing.

- Examine bushings for cracks, oil saturation, or looseness. They should be firm, not mushy.

- Check all fasteners on control arms and steering knuckle. Tighten any that are loose.

- Look at tire wear patterns. A feather‑edge wear may point to alignment, while cupping suggests shock issues.

If anything looks out of place, note it - you’ll need the details when you move to the road test.

Road‑Test Diagnostic Steps

The car’s behavior on the road often tells you more than a static inspection. Follow these simple maneuvers:

- Bounce Test: Push down hard on the front or rear bumper and release. The car should rebound once and settle quickly. Multiple bounces indicate worn shocks or struts.

- Turn Test: At low speed, make a sharp left, then a right. Excessive body roll or a delayed steering response points to weak dampers or broken springs.

- Brake Test: Lightly tap the brakes while cruising. If the front dips dramatically, the front springs may be sagging.

- Uneven Road Test: Drive over a speed bump or a pothole. Listen for rattles; a single knock often means a loose control arm bolt.

Document where the noise or feel occurs - front vs. rear, left vs. right. That narrows the component pool.

Tools that Make Diagnosis Easy

- Ride‑Height Gauge: Measures the distance from the axle to the chassis. Compare readings to factory specs (usually in the owner’s manual).

- Shock Test Stiffness Gauge: Some auto parts stores rent a handheld device that quantifies damper force.

- Jack and Jack Stands: Lift the vehicle safely to inspect underneath. Never rely on a jack alone.

- Torque Wrench: Ensures bolts, especially on control arms, are tightened to manufacturer specifications.

These tools are inexpensive and let you confirm a suspicion before buying replacement parts.

When to Call a Professional

Even the savviest DIYer hits a wall. Consider a workshop if you notice any of the following:

- Severe rust on suspension mounts - corrosion can weaken attachment points.

- Persistent noises after tightening all visible bolts.

- Complex issues like a broken steering knuckle or frame damage.

- Lack of proper alignment tools - a professional alignment machine can correct camber, caster, and toe to exact tolerances.

Professional diagnosis usually includes a computerized suspension analysis, which can spot hidden faults that a visual check might miss.

Preventive Maintenance Tips

- Lubricate rubber bushings with a silicone‑based spray every 12months.

- Replace worn shocks or struts every 80,000‑100,000km, or sooner if you notice bounce.

- Get a wheel alignment check after hitting a pothole or after installing new tires.

- Inspect tire pressure weekly - under‑inflated tires put extra strain on suspension components.

- Swap front and rear tires on all‑wheel‑drive cars every 6months to even out wear.

Following these routines keeps the suspension healthy and extends vehicle life, saving you time and money.

Frequently Asked Questions

How often should I inspect my car’s suspension?

A visual check every 6months is enough for most drivers. If you frequently drive on rough roads, add a quick inspection every 3months.

Can I replace a single shock absorber, or do I need to replace them in pairs?

It’s best to replace them in pairs because wear is usually symmetrical. Replacing one side only can lead to uneven handling.

What does a “clunk” sound mean when I go over a bump?

A clunk often points to a loose bolt, a broken bushing, or a worn control arm. Pinpoint the location (front‑left, rear‑right) and check the corresponding components.

Is a bounce test reliable for all vehicle types?

The bounce test works on most passenger cars and light trucks. Heavy‑duty trucks often have additional air‑suspension systems that require pressure checks instead.

Do I need a wheel alignment after replacing shocks?

Yes. New shocks can change ride height slightly, which may alter alignment angles. A quick alignment check ensures the suspension works as designed.