Flywheel Noise Diagnostic Tool

What kind of noise are you hearing?

Additional symptoms

Your Diagnosis

Recommended next steps

The moment you hear a strange flywheel noise, it’s a red flag that something isn’t right under the hood. The Flywheel is a heavy steel disc attached to the Crankshaft and its job is to smooth out the engine’s power pulses. When it begins to fail, the sounds it makes can range from a faint whine to a grinding roar, and each tells a different story.

Why Listening Matters

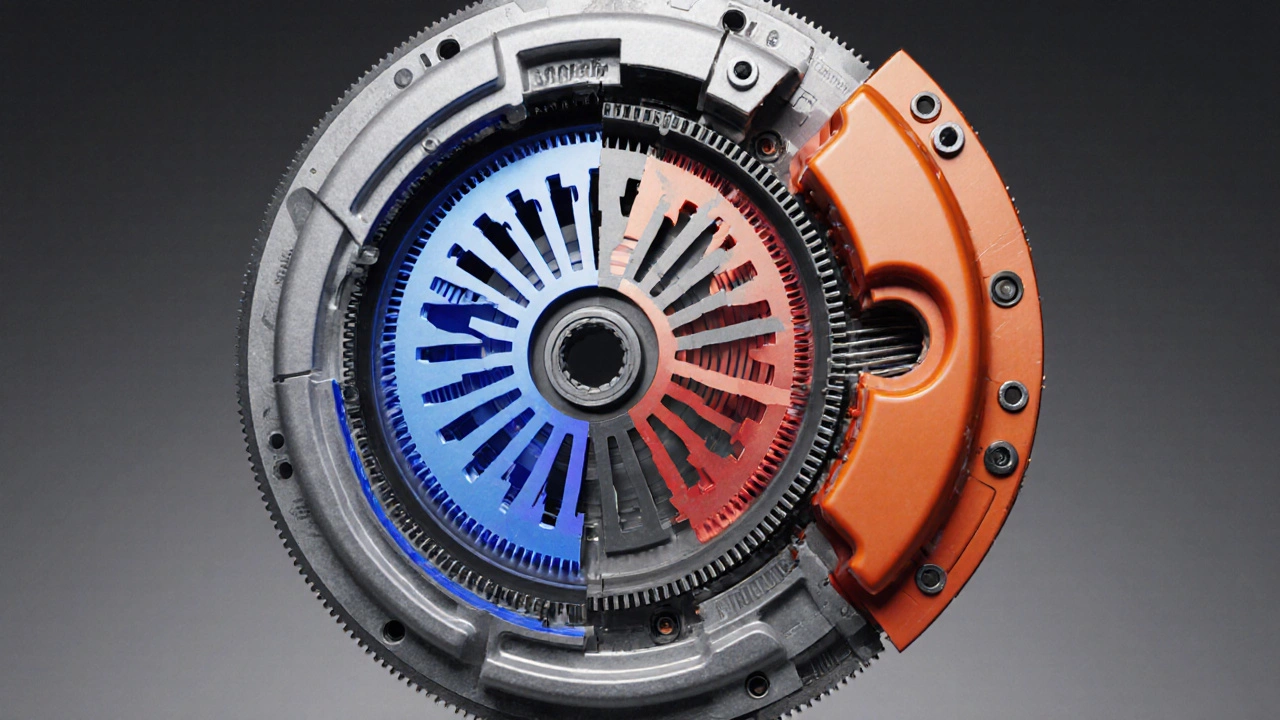

Noise is the engine’s way of shouting for help before a catastrophic failure. Catching the right sound early can save you from a busted transmission, a broken starter motor, or an expensive flywheel replacement. In the world of clutch kits, the flywheel is the anchor point for the clutch disc, pressure plate, and throw‑out bearing, so any issue reverberates through the entire drivetrain.

Common Flywheel Sounds and Their Meanings

- Squeal or high‑pitched whine - Usually a sign that the flywheel surface is glazed or that the clutch friction material is slipping against a smooth flywheel.

- Grinding or metallic chatter - Indicates worn or broken Flywheel teeth or a damaged pressure plate contacting the flywheel incorrectly.

- Rattling at idle - Often caused by a loose flywheel bolt, a cracked flywheel, or excessive engine vibration transferring through a worn Harmonic balancer.

- Clunk or thump when shifting gears - May come from a cracked flywheel, a failing throw‑out bearing, or a mis‑aligned clutch assembly.

- Whining that changes with engine speed - Typical of a failing starter motor gear engaging with the flywheel’s ring gear, especially during cold starts.

How to Diagnose the Noise

- Start the engine and listen from the passenger side where the flywheel is most audible.

- Increase RPM slowly; note whether the pitch rises (whine) or stays constant (grind).

- Turn off the engine, then rev it using the starter. A change in sound when the starter is engaged often points to the Starter motor gear.

- Put the car in gear with the clutch fully depressed and gently release. If the noise intensifies, focus on the clutch, pressure plate, and throw‑out bearing.

- Use a mechanic’s stethoscope on the flywheel housing while the engine runs. A localized rattling points to a cracked flywheel or loose bolts.

- Check for excess engine vibration using a handheld accelerometer or simply feel the vehicle. High vibration can indicate an unbalanced flywheel or a worn harmonic balancer.

Components That Can Mimic Flywheel Noise

Not every clunk comes from the flywheel itself. Here’s a quick rundown of parts that often get blamed:

- Clutch - A worn clutch disc can slip and create a high‑pitched squeal that feels like flywheel noise.

- Pressure plate - If its springs are fatigued, they’ll tap against the flywheel each time you engage the clutch.

- Throw‑out bearing - A bearing that’s grinding will sound like metal on metal during clutch release.

- Transmission - Internal gear wear can echo through the drivetrain, making it hard to isolate the source.

Inspecting the Flywheel

When the noise diagnosis points to the flywheel, it’s time for a hands‑on inspection.

- Disconnect the battery and remove the transmission to expose the flywheel.

- Visually check for cracks, surface scoring, or rust spots. Even a hairline crack can cause rattling.

- Spin the flywheel by hand. Listen for uneven clicks that indicate a broken tooth.

- Measure the flywheel’s thickness at several points with a micrometer. A variance of more than 0.5 mm usually means it’s warped.

- Inspect the bolt pattern. Loose or missing bolts will create a distinct rattling that worsens with engine vibration.

- Check the flywheel’s ring gear for tooth wear or chipped edges-common when the starter gear engages poorly.

Repair vs. Replace

Not every issue warrants a brand‑new flywheel. Here’s when you can consider a repair:

- Surface glazing - a professional resurfacing can restore a smooth finish.

- Minor scoring - polishing with a fine abrasive may be enough.

- One or two cracked teeth - if the rest of the disc is solid, a machinist can weld and re‑balance.

If you encounter any of the following, replacement is the safer route:

- Cracks larger than 1 cm.

- Multiple missing or chipped teeth.

- Significant warp or out‑of‑round condition.

- Corrosion penetrating deep into the metal.

In Australia, a new flywheel for a typical 2.0 L sedan runs between AUD 400-600, plus labor of roughly 4‑6 hours. Resurfacing can cost around AUD 150-250, but remember that a repaired flywheel must be re‑balanced, adding extra time.

Preventive Maintenance Tips

- Torque flywheel bolts to the manufacturer’s specification (usually 80-100 Nm) using a calibrated wrench.

- Replace the clutch disc and pressure plate together when you notice any slippage or unusual noises.

- Inspect the starter gear and ring gear at each clutch service; a worn starter can gouge the flywheel.

- Keep the engine oil at the correct level and change it on schedule - clean oil reduces wear on the harmonic balancer and flywheel bearings.

- After any major engine work, run the engine at idle for 10-15 minutes and listen for residual rattles before re‑installing the transmission.

Quick Reference Table

| Noise Type | Likely Source | Urgency | Next Step |

|---|---|---|---|

| Squeal/whine | Glazed flywheel surface or slipping clutch | Medium | Check clutch disc, consider resurfacing flywheel |

| Grinding | Damaged flywheel teeth or pressure‑plate contact | High | Inspect ring gear, replace flywheel if teeth missing |

| Rattling at idle | Loose bolts, cracked flywheel, harmonic balancer | High | Tighten bolts, check for cracks, replace balancer if needed |

| Clunk/Thump on shift | Throw‑out bearing wear or flywheel crack | Medium‑High | Inspect bearing, check flywheel for fractures |

| Whine that changes with starter | Starter motor gear wearing against flywheel ring gear | Low‑Medium | Service starter, inspect ring gear for wear |

When to Call a Professional

If you’re not comfortable removing the transmission or you spot a crack larger than a coin, it’s time to let a qualified mechanic take over. A mis‑balanced flywheel can introduce vibration that damages the engine mounts, so don’t gamble on a DIY fix when the stakes are high.

Bottom Line

Every odd sound from under the hood is a clue. By matching the noise to its typical cause-whether it’s a squeal from a glazed flywheel, a grind from broken teeth, or a rattling from loose bolts-you can decide quickly if a simple part swap will do or if a full flywheel replacement is unavoidable. Keep an ear out, act fast, and you’ll keep your clutch kit-and your car-running smoothly.

What does a high‑pitched squeal from the flywheel mean?

A high‑pitched squeal usually points to a glazed or overly smooth flywheel surface that’s causing the clutch disc to slip. The solution is to either resurface the flywheel or replace the clutch disc and pressure plate together.

Can a loose flywheel bolt cause rattling at idle?

Yes. If any of the flywheel mounting bolts are under‑torqued or missing, the whole assembly can vibrate and produce a rattling sound that’s most noticeable when the engine is idling.

Is it safe to drive with a cracked flywheel?

Driving with a cracked flywheel is risky. The crack can spread, lead to loss of balance, and eventually cause severe engine vibration or catastrophic failure. Replace it as soon as possible.

How do I know if the starter motor is the culprit?

If the whining changes pitch when you crank the engine with the key (or use a remote starter), the starter gear is likely chewing on the flywheel’s ring gear. Listen for the change and inspect the starter’s pinion for wear.

Should I replace the flywheel when I change the clutch?

If the flywheel shows any signs of wear-cracks, scored teeth, or excessive rust-replace it. Even if it looks okay, many mechanics recommend resurfacing to ensure a perfect mating surface for the new clutch.